About Us

Your trusted manufacturer of PTFE and more PTFE composite parts

Jinshiling (Heyuan) Technology Co., Ltd. was established in 2021, with a registered capital of 20 million yuan and its own industrial park of 38,000 square meters. The company focuses on fluorine plastic plate, rod, pipe and shaped parts, molded parts, filling parts and other polymer material products R & D and manufacturing. At present, it has the world’s leading 4-meter large PTFE sealing ring production equipment, CNC equipment and advanced precision testing instruments, and has a standardized dust-free workshop to ensure the quality and cleanliness of products. The products are widely used in aerospace, semiconductor, solar energy, hydrogen energy, oil and gas, chemical processing, food and beverage, industry, machinery, automotive and medical industries. Kingling’s positioning is “a high-end brand enterprise that only does new materials”, taking “gold quality, leading technology” as the company’s business philosophy, and serving the global fluoroplastic demand customers. Provide solutions and quality service

The best PTFE product manufacturer

The company focuses on the R&D and manufacturing of polymer material products such as threaded parts, seals, special-shaped parts, molded parts, and filling parts.

Currently it has the world’s leading 4-meter large PTFE sealing ring production equipment, CNC equipment and advanced precision testing instruments.

Workshop environment

Clean workshop production, less impurities, can be used in food, medical, semiconductor industries

High quality material

Only do new materials, no recycled materials, to maintain the highest quality product performance;

Full range, special can be determined

Top technology advantages, the maximum production of 4 meters wide turning board, 14mm thick 12 meters long turning board; The molded plate can finally reach a thickness of 300mm;

Advanced equipment, accurate size

The use of advanced equipment, the thickness of the board is more accurate, so that you will not be too rough, thickness tolerance difference is too big chagrin.

Application field

Clean workshop production, less impurities, can be used in food, medical, semiconductor industries

Dust-free clean workshop

Dust-free workshop production, greatly reduce the impact of impurities, to ensure the purity of ptfe, fep, pfa hose products, in line with FDA standards, can be directly applied to food, medical, semiconductor and other high-purity requirements of the industry.

Dust-free clean workshop

Dust-free workshop production, greatly reduce the impact of impurities, to ensure the purity of ptfe, fep, pfa hose products, in line with FDA standards, can be directly applied to food, medical, semiconductor and other high-purity requirements of the industry.

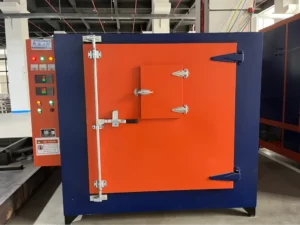

Advanced Equipment

Advanced technology, good equipment, fluorine plastic products complete

It can produce the largest PTFE rod in the industry, with a length of 4 meters and a diameter of 500mm.

The maximum size of the ptfe molded plate can reach 2000mm long * 2000mm wide * 390mm thick.

The maximum thickness of the ptfe turning plate can reach 12 meters long * 4000mm wide * 14mm thick,

It can also produce high purity PFA tubes for nanoscale semiconductors. To meet the special needs of customers for PTFE products.

Advanced Equipment

Advanced technology, good equipment, fluorine plastic products complete

It can produce the largest PTFE rod in the industry, with a length of 4 meters and a diameter of 500mm.

The maximum size of the ptfe molded plate can reach 2000mm long * 2000mm wide * 390mm thick.

The maximum thickness of the ptfe turning plate can reach 12 meters long * 4000mm wide * 14mm thick,

It can also produce high purity PFA tubes for nanoscale semiconductors. To meet the special needs of customers for PTFE products.

What ptfe products do you need, please tell me

After receiving your message, we will reply you in time