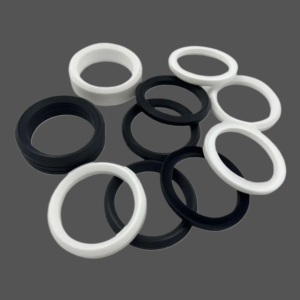

PTFE Rings

PTFE Piston Rings and Guide Rings (Rider rings) for dry-running applications are currently a focal point of technical development.

They significantly reduce a machine’s operating costs and, in today’s increasingly environmentally aware society, make it easier for operators to fulfill stricter environmental legislation.

-

PTFE Rings

ptfe backup rings

-

PTFE Rings

ptfe encapsulated o rings

-

PTFE Rings

PTFE Guide Rings

-

PTFE Rings

ptfe piston rings

-

PTFE Rings

ptfe spacer ring

Piston Guide Rings features

Chemical and thermal resistance

Temperature range from –200°C to +260°C

Suitable for use with non-hard-ened contact surfaces

High bearing capacity, pressure resistance and low wear

No stick-slip, Minimal lubrication required

Extremely low breakaway forces

Large compound selection

Easy installation due to cut grooves

Guide Rings & Piston Rings Designed For Your Application

Compressors operating under full- and low-lube conditions

Gas rotary pumps

Expansion machinery

Liquid gas and vacuum pumps

Rocking piston pumps

Rotary compressors for loading/unloading of silos

Generation of oil-free compressed air for the

food processing industry, pharmaceutical industry, and dentistry

Compressed air for the craft and do-it-yourself market

Pneumatic hammer drills

Automotive technology, including ride leveling

and air-conditioning systems

Guide Rings Material Selection

| Material Name | Compound % | Main Properties | Color |

| PTFE | / | Very low coefficient of friction and excellent chemical resistance.

FDA approved. | White |

| Glass Filled PTFE | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

| Carbon Filled PTFE | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

| Graphite Filled PTFE | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way. | Black |

| Bronze Filled PTFE | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance. | Dark Brown |

| Molybdenum disulphide(MoS2) Filled PTFE | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction. | Blue azure |

| PEEK Filled PTFE | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications. | Light Brown |

| PEEK | / | Excellent mechanical properties including strength, rigidity, impact resistance, low wear rate and low coefficient of friction, retained over a wide range of service temperatures. | Light Brown |

| PEEK compound | / | Improves technical and chemical properties like deformation under load, wear resistance, thermal expansion and electrical conductivity. | / |

| PVDF | / | Resistant to UV radiation and offers high mechanical strength and abrasion resistance. | Beige |

| PCTFE | / | Better mechanical properties than other fluoropolymers, low permeability. | Translucent |

| PFA | / | Excellent chemical and temperature resistance, electrical insulation and excellent processability | Natural |

best PTFE Guide Ring Manufacturer & suppliers

We supply the highest quality PTFE guide rings and piston rings for several different industries. We also offer custom designed materials. You can also get free samples of PTFE rings or fluoropolymer parts from us. Our ptfe piston rings have the following characteristics