ptfe molded parts

How to reduce the cost of ptfe parts processing?Molding processing is one of the best ways, our company produces all kinds of ptfe molded parts, through the iso certification, has a clean dust-free workshop, the production of ptfe parts for food, semiconductor, aerospace and other industries

-

ptfe molded parts

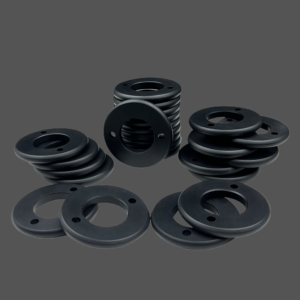

black ptfe parts

-

ptfe molded parts

cnc machining ptfe parts

-

ptfe molded parts

Custom ptfe molded parts

-

ptfe molded parts

machined ptfe parts

-

ptfe molded parts

Molded PTFE Parts

-

ptfe molded parts

PTFE Bushings

-

ptfe molded parts

PTFE Fasteners

-

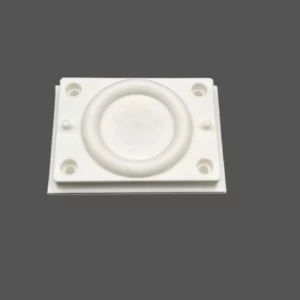

ptfe molded parts

ptfe insert

-

ptfe molded parts

PTFE Irregular Shaped Parts

-

ptfe molded parts

PTFE Molding & Machining

-

ptfe molded parts

PTFE Pall ring

-

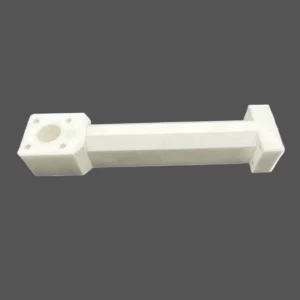

ptfe molded parts

Ptfe plastic moulded connectors

What is molded PTFE?

PTFE molding refers to the process of pressing PTFE (polytetrafluoroethylene) particles or powder through pressure and heating, melting it at high temperature and injecting it into the mold for pressing molding.

Advantages of ptfe molding

The ptfe molding process can produce ptfe parts with high precision and complex shapes

ptfe parts manufactured by the ptfe molding process usually have a smooth finish and do not require additional surface treatment

ptfe molding process can effectively use raw materials, high material utilization rate, reduce waste generation

The ptfe molding process can achieve automated production, reduce manual operation, and improve the consistency and stability of production

The ptfe molding process can achieve precise control of the performance of the part by adjusting the mold design and process parameters to meet the requirements of different applications.

The ptfe molding process can usually be produced in large quantities, improving results and saving costs.

What are the key factors of teflon molding?

Mold design

Molds must be precisely designed to create the desired shape and size of the teflon product. To ensure that polytetrafluoroethylene evenly filled mold, no defects.

Polytetrafluoroethylene material type

Different grades of teflon have different properties, such as different levels of purity, tensile strength and elongation.

Process parameter

Process parameters, such as pressure, speed, mold temperature, etc., must be carefully controlled to ensure the production of high-quality PTFE products.