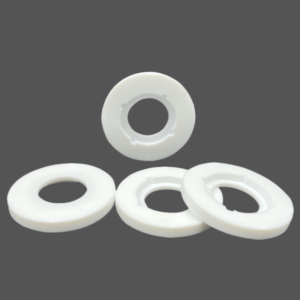

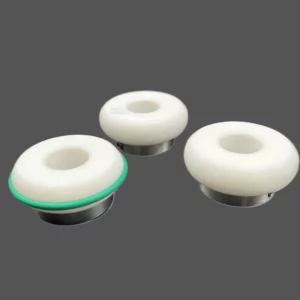

Ball Valve Seats

Our extensive experience in CNC machining and Fluoropolymers assures close tolerance machining. This guarantees that the valve seats will fit and seal in whatever climate the seals are used.

We inspect production batches by electronic imaging and specify the highest quality raw materials. We can offer valve seats in filled and modified PTFEs and application specific engineering of valve seats, also combining stainless steel with fluoropolymers or FEP Encapsulated O-Rings in valve seat designs.

-

Ball Valve Seats

ptfe Ball Valve Seats

-

Ball Valve Seats

PTFE Bearing Balls

-

Ball Valve Seats

PTFE Plastic Balls

-

Ball Valve Seats

ptfe seal seats

-

Ball Valve Seats

ptfe valve seat

Ball Valve Seat function

Sealing: One of the primary functions of the ball valve seat is to create a tight seal against the ball when the valve is closed. This prevents any leakage of fluid through the valve when it’s not intended to flow.

Preventing Leakage: The design of the seat ensures that even under high pressure, there is minimal or no leakage past the seal. This is especially crucial in applications where any leakage could lead to safety hazards, environmental contamination, or loss of valuable fluids.

pfte ball valve seat & ball performance

- Low friction to reduce stem torque

- Excellent wear resistance

- Good stress recovery

- Sufficient elasticity to maintain a solid seal

- Dimensional stability

- Chemical compatibility with the media involved

Your Trusted PTFE Ball Valve Seat Manufacturer

Leading manufacturers of PTFE ball valve seats often provide customization options to meet specific application requirements. They may offer a range of seat sizes, shapes, and configurations tailored to different valve designs and operating conditions. Additionally, manufacturers may provide engineering support and technical expertise to assist customers in selecting the most suitable PTFE ball valve seats for their applications.