PTFE Labware

We primarily machine these from virgin grade PTFE and Modified PTFE to suit applications requiring chemical resistance, high purity and the ability to handle a broad operating temperature range.

-

PTFE Labware

Corrosion-resistant ptfe beaker

-

PTFE Labware

ptfe beaker 250ml

-

PTFE Labware

PTFE Magnetic Mixer Stir Bars Gear shape

-

PTFE Labware

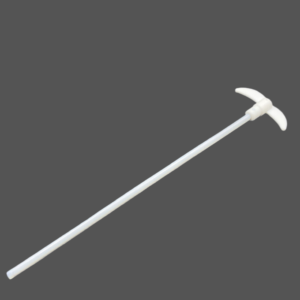

PTFE Propeller

-

PTFE Labware

stir bar used in laboratory

Fluoropolymer Lab Supplies features

(Polytetrafluoroethylene Plastic) is a good choice for labware because of its resistance to corrosive elements that many other plastics are unable to stand up to.

Chemical Resistance

The chemical resistance of PTFE is almost total over its working temperature range. Reaction is limited to some compounds with free electrons such as sodium in liquid ammonia and some fluorine compounds at high temperature and pressure. Halogens will penetrate PTFE but without apparent reaction.

Thermal Stability

The thermal stability of PTFE is outstanding. The material can be used to ca. 280˚C yet there is no embrittlement in liquid helium. Thermal degradation does not commence until about 400˚C. PTFE does not melt to form a liquid phase.

Insolubility & Purity

The PTFE we use conforms to USP Class VI and FDA requirements and is intrinsically pure and contains no additives. PTFE is insoluble in all known solvents except under extremes of pressure and temperature and will not contaminate media by dissolution.

Electrical Insulation

Fluoropolymers have excellent electrical insulation properties, which are suitable for use in electrical and electronic experiments where insulation is required

Labware Materials Selections

| Material Name | Compound % | Main Properties | Color |

| PTFE | / | Very low coefficient of friction and excellent chemical resistance.

FDA approved. | White |

| Glass Filled PTFE | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

| Carbon Filled PTFE | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

| Graphite Filled PTFE | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way. | Black |

| Bronze Filled PTFE | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance. | Dark Brown |

| Molybdenum disulphide(MoS2) Filled PTFE | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction. | Blue azure |

| PEEK Filled PTFE | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications. | Light Brown |

| PEEK | / | Excellent mechanical properties including strength, rigidity, impact resistance, low wear rate and low coefficient of friction, retained over a wide range of service temperatures. | Light Brown |

| PEEK compound | / | Improves technical and chemical properties like deformation under load, wear resistance, thermal expansion and electrical conductivity. | / |

| PVDF | / | Resistant to UV radiation and offers high mechanical strength and abrasion resistance. | Beige |

| PCTFE | / | Better mechanical properties than other fluoropolymers, low permeability. | Translucent |

| PFA | / | Excellent chemical and temperature resistance, electrical insulation and excellent processability | Natural |