PTFE molding manufacturer

14 years manufacturing and processing experience of PTFE products

ptfe parts manufacturers & ptfe material supplier

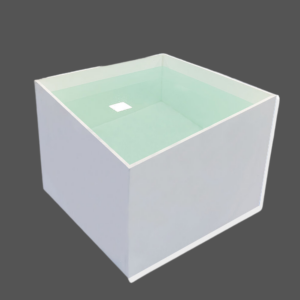

Jinshiling (Heyuan) Technology Co., Ltd. has an industrial park plant 38,000 square meters. The company focuses on ptfe plate, ptfe rods, ptfe tube and ptfe shaped parts, ptfe moulded parts, ptfe filling parts and other ptfe material products R & D and manufacturing. At present, it has the world’s leading 4-meter large PTFE sealing ring production equipment, CNC equipment and advanced precision testing instruments, and has a standardized dust-free workshop to ensure the quality and cleanliness of products.

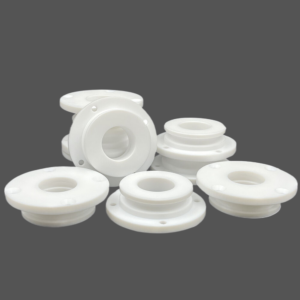

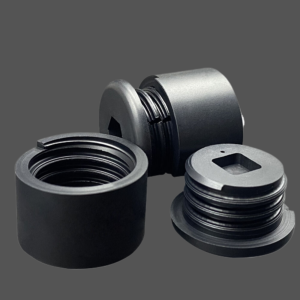

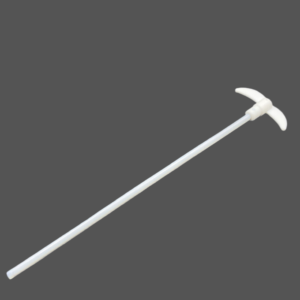

ptfe machined parts

jinshiling Manufacturing has a reputation for machining quality ptfe parts. We can machine intricate parts on our CNC machines and CNC turning centers.

PTFE (more commonly known as Teflon) is an extremely resilient plastic, ideal for machine parts that require high impact strength and durability. With low and high temperature resistance, corrosion resistance, weather resistance, high lubrication, non-adhesion, non-toxic, non-combustible, antioxidant characteristics

best ptfe manufacturers

ptfe machining parts customized wholesale

Leave your email

Have or do not have the ptfe products you need, leave your email so that we can contact you

goldencollar ptfe manufacturers

ptfe machining parts customized wholesale

Leave your email

Have or do not have the ptfe products you need, leave your email so that we can contact you

Why Choose Us

Source factory

ptfe product source factory, supports customization of various fluorine material products

advanced equipment

with the advanced automated production line of the PTFE products Globally leading technology

dust-free workshop

High-cleanliness equipment workshop, capable of producing ptfe products for medical, food, and semiconductor industries

Quality assurance

We have a strict quality management system and ISO9001 certification to ensure that our products are flawless.

Source factory

ptfe product source factory, supports customization of various fluorine material products

advanced equipment

with the advanced automated production line of the PTFE products Globally leading technology

dust-free workshop

High-cleanliness equipment workshop, capable of producing ptfe products for medical, food, and semiconductor industries

Quality assurance

We have a strict quality management system and ISO9001 certification to ensure that our products are flawless.

PTFE FAQ

Essentially, the only difference lies in the name. PTFE is the shortened name of the chemical polytetrafluoroethylene, and Teflon is the trade name of the same polymer. If you are looking for a highly flexible, non-stick material that is chemical, electrical and thermal resistant, look no further than PTFE.

After product and price confirmation, you can require for samples to check our quality. the samples are free and will be ready for delivery in 3-5 days. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

Yes. we are a perfessional manufacturer who can provide you OEM service.

Nearly 50% of all PTFE produced is used for wiring in aerospace and computer applications

For industrial use, PTFE’s low friction lends itself to plain bearings, gears, slide plates, and other applications with sliding action of parts,

Due to its high temperature rating and extreme non-reactivity, PTFE is often used as containers, expansion joints, liners in hose assemblies, industrial pipelines, and other applications involving corrosive and reactive chemicals.

We use selected imported raw material to make sure good physical property, And we also could change the raw material compound formula , to meet your special processing conditions.。

Of course we can, and some of them are free, but the shipping cost you need pay.

ptfe blog

What is the temperature range of ptfe?

The PTFE, sometimes referred to as “Teflon” is an strange material since it’s a thermoplastic however, it is also a thermoset. Although other thermoplastics can be reused after moulding, PTFE cannot. Furthermore, although the PTFE temperature ranges from between -400 and +550 degrees Fahrenheit the material begins its transition process at various points, which means it is that PTFE substance shifts because of the temperature of its surroundings. With PTFE temperature limits of 400 degrees and the maximum temperature of

ptfe hose application and advantages detailed explanation

Polytetrafluoroethylene (PTFE) hoses have become indispensable in numerous industries due to their exceptional properties and versatility. From aerospace to pharmaceuticals, PTFE hoses find applications in diverse fields. This essay delves into the specifications, advantages, applications, dimensions, and lifespan of PTFE hoses, highlighting their significance in modern engineering. Specifications of PTFE Hoses: PTFE hoses are constructed from a synthetic fluoropolymer of tetrafluoroethylene. These hoses exhibit remarkable resistance to heat, chemicals, and extreme conditions. PTFE hoses typically have a temperature range from

Innovative Uses for PTFE Sheets Beyond Ordinary Applications

PTFE (polytetrafluoroethylene) sheets are versatile materials known for their non-stick properties and resistance to heat, chemicals, and weathering. They are commonly used by industries such as food processing, electronics, and pharmaceuticals. However, they have some unique applications. Art and Crafts PTFE sheets are a great non-stick material for a variety of art and crafts projects. Artists can use them to mix paints, or for fine paintwork. Crafters can work with resin or hot glue guns on Fluoropolymer Sheets. Modeling and Prototyping :Polytetrafluoroethylene Sheets are useful

Recommended by 5 top ptfe rod manufacturers

Polytetrafluoroethylene rod is suitable for processing a variety of liners, seals and lubrication materials working in corrosive media and electrical insulation parts used at various frequencies, unfilled polytetrafluoroethylene resin (may contain recycled polytetrafluoroethylene resin) molded by extrusion, extrusion or calendering extrusion process. PTFE rods are a vital component of many industrial and commercial products. Although PTFE may not be as well known as materials such as steel or aluminum are, it is an essential and versatile material that can be used

What Ptfe Products Do You Need, Please Tell Me

After receiving your message, we will reply you in time