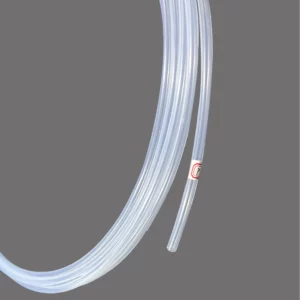

Polytetrafluoroethylene (PTFE) hoses have become indispensable in numerous industries due to their exceptional properties and versatility. From aerospace to pharmaceuticals, PTFE hoses find applications in diverse fields. This essay delves into the specifications, advantages, applications, dimensions, and lifespan of PTFE hoses, highlighting their significance in modern engineering.

Specifications of PTFE Hoses:

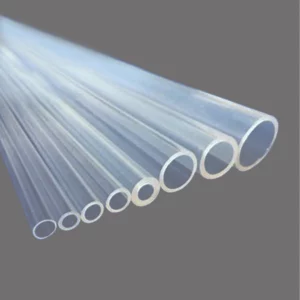

PTFE hoses are constructed from a synthetic fluoropolymer of tetrafluoroethylene. These hoses exhibit remarkable resistance to heat, chemicals, and extreme conditions. PTFE hoses typically have a temperature range from -70°C to 260°C (-100°F to 500°F), making them suitable for both low and high-temperature applications. They possess a low coefficient of friction, excellent dielectric properties, and are non-reactive to most chemicals. Additionally, PTFE hoses are non-toxic, making them suitable for food and pharmaceutical industries.The more common pte pipe specifications and sizes are:tube ptfe 2×4,2mm ptfe hose,ptfe hose 3/4,ptfe hose 3/8

Applications of PTFE Hoses:

Aerospace: PTFE hoses have been extensively used for aerospace applications because of their light weight, resistance to extreme temperature, and compatibility to aviation fluids. Fuel lines, hydraulic systems and pneumatic systems are all used with them.

Automotive: PTFE flexible tube can be found in the brake system, fuel line, and transmission system of automobiles. These hoses are ideal for these applications because they can withstand high temperatures and corrosive liquids.

Chemical Processing: PTFE hoses have a wide application in chemical processing plants, where the resistance to corrosive substances is essential. They are used to transport acids, alkalis and other corrosive materials safely.

PTFE hoses are widely used in the pharmaceutical and food industries because of their non-toxic properties and resistance to contamination. They can be used to convey a variety of fluids including pharmaceutical ingredients, foods, and beverages.

PTFE tube can be used for medical equipment and devices due to their biocompatibility. Catheters, dental instruments and surgical equipment are all examples of where they can be used.

PTFE flexible tube have excellent dielectric properties and are used in the electronics industry. They are used for cable assemblies, wire harnesses and semiconductor manufacturing.

PTFE hoses can be used in cryogenic applications because of their low temperature resistance. These hoses are used to handle liquefied gas and cryogenic fluids.

Petrochemical Industry: PTFE hoses can be used in the petrochemical sector to transport petroleum-based products and oils.

Advantages of PTFE Hoses:

Chemical Resistance: PTFE hoses are resistant to a variety of chemicals, acids and solvents. They can be used for handling corrosive materials.

High Temperature Resistant: PTFE flexible tube are resistant to extreme temperatures ranging between -70degC and 260degC. (-100degF up to 500degF).

Low Friction Coefficient : PTFE hoses are designed with a low friction coefficient, which minimizes the pressure drop and reduces fluid resistance, resulting in an efficient fluid transfer.

Non-stick Surface : ptfe flexible tube are non-stick, preventing contaminants from adhering to the surface and facilitating cleaning.

Non-Toxicity PTFE hoses have FDA approval for food and pharmaceutical applications. This ensures product safety.

Flexible: Ptfe soft tube have a high degree of flexibility, allowing for easy routing in complex systems. They can be routed without kinking and collapsing.

Weather Resistant: PTFE hoses resist weathering, UV radiation and ozone making them ideal for outdoor applications.

Electrical Insulation: PTFE tubes have excellent electrical insulation properties and are therefore ideal for electronic and electrical applications.

PTFE Tubing Dimensions: PTFE hoses are available in various dimensions to suit different application requirements. Common dimensions include inner diameters (ID) ranging from 1/8″ to 2″, with corresponding outer diameters (OD) depending on the wall thickness. Wall thicknesses typically range from 1/32″ to 1/4″. Custom dimensions can also be manufactured to meet specific requirements.

PTFE Hose Lifespan: The lifespan of PTFE hoses varies depending on factors such as operating conditions, temperature, pressure, and mechanical stresses. However, PTFE hoses are known for their durability and long service life compared to other hose materials. With proper installation, maintenance, and handling, PTFE hoses can last for several years, even in demanding environments.